How Voltaiq Accelerates Battery Cell Selection

Combining testing and modeling with Voltaiq to make more confident design decisions

Introduction

Battery cell selection is a critical early decision in automotive programs. Teams must evaluate cells from multiple suppliers and understand how they perform under real operating conditions, not just based on datasheet specifications.

The challenge is turning large volumes of battery test data into clear, comparable insights quickly enough to inform early decisions. Voltaiq enables a data-driven approach by centralizing test data, standardizing analysis, and connecting performance testing with modeling. This helps teams move faster from testing to confident cell selection.

Comparing Cell Performance Across Suppliers

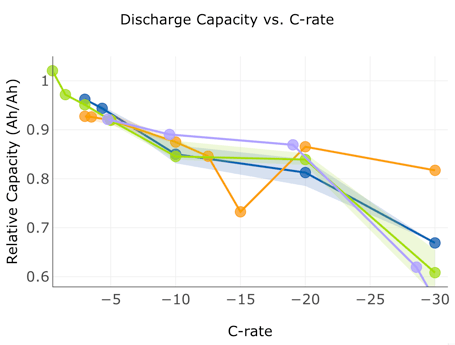

Early in an automotive program, multiple candidate cells are tested to understand how they perform under standardized conditions. For example, cells that appear similar at low discharge rates often behave very differently at higher rates that are relevant to real vehicle operation.

Figure 1. Capacity Retention at Different C-rates for Various Cell Suppliers

By standardizing analysis across suppliers, Voltaiq helps teams quickly identify performance differences and eliminate options that do not meet program requirements. This accelerates early down-selection and reduces reliance on manual data processing.

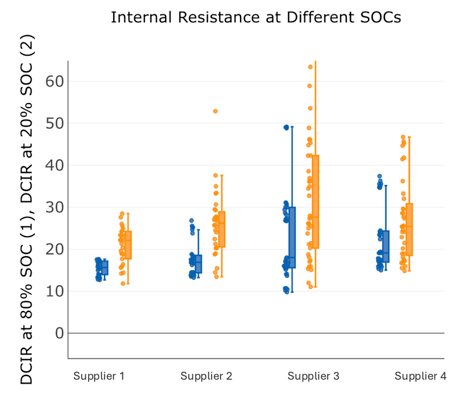

Understanding Resistance Behavior and Variability

Beyond capacity, internal resistance is a key factor in real-world battery performance. Higher resistance leads to increased heat generation, reduced efficiency, and limited power availability, especially at lower states of charge. Cells with higher resistance or greater variability are more likely to experience elevated heat generation and accelerated degradation under demanding operating conditions.

Figure 2. DC Internal Resistance Comparison for Cells from Different Suppliers

By surfacing resistance trends early, Voltaiq helps teams identify potential thermal and reliability risks before they appear in vehicle testing. This enables faster elimination of high-risk options and supports more informed cell selection decisions.

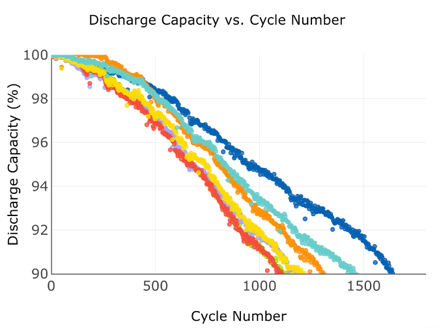

Modeling Degradation and Predicting Lifetime With Voltaiq Studio

Long-duration cycling tests are essential for understanding battery lifetime, but they often extend beyond early cell selection milestones. To support faster decisions, test data needs to be translated into predictive insight. Voltaiq Studio allows teams to use measured cycling data to build and customize their own degradation models.

Figure 3. Experimentally Obtained Cycling Data from Supplier 1

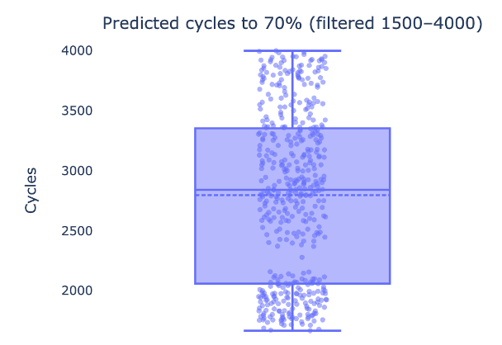

By applying these models to real test data, teams can estimate cycle life and assess variability across cell populations earlier in the program. This helps quantify lifetime risk without waiting for tests to run to completion, supporting more confident and timely cell selection decisions.

Figure 4. Estimated Cycle Life for Supplier 1 using Voltaiq Studio (User Defined Model)

Key Takeaways

- Voltaiq enables fast, standardized comparison of battery cells across suppliers.

- Early insight into performance, and lifetime helps identify risk before designs and sourcing are locked.

- By connecting testing, analytics, and modeling in one platform, Voltaiq accelerates confident battery cell selection.